Materials

The mixed milk (cow and buffalo milk; 4.6% fat, 8.6% MSNF) and cream (42.0% fat) required for standardization were purchased from Vidya Dairy, Anand (Gujarat), India. Skimmed milk powder (SMP) of ‘Sagar’ brand was used as a source of non-fat milk solids (MSNF). Cane sugar of ‘Madhur’ brand was purchased from the local market in Anand, India. Pectin (high methoxy type) and carrageenan (RM-1576) were purchased from HiMedia, Mumbai, while glycerol monostearate (GMS) was purchased from Loba Chemie, Mumbai. Orange dye of ‘Blossom’ brand was purchased from Raunak Enterprises, Mumbai. Fresh oranges of Valencia variety (Citrus sinensis cv. Valencia) were from Dev Exotica, Anand, India. Orange Crush was purchased from Mapro Foods Pvt. Ltd., Panchgani (Maharashtra). Delvo DSL direct set freeze dried yogurt starter culture RST-776 was from DSM Food Specialties. The cane sugar and oranges used in this study were in accordance with the national guidelines and laws of India.

equipment

The equipment used were (i) a homogenizer from M/s. Goma Engineering Pvt. Ltd., Mumbai, (ii) a batch ice cream freezer (8.0 L/batch) from M/s. Pal Engineers, Ahmedabad, (iii) a jet tunnel hardener from M/s. Pal Engineers, Ahmedabad, Gujarat, India (iv) a vacuum tray dryer from M/s. Perfect Engineering and Allied Works Pvt. Ltd., Vadodara, Gujarat, India and the apparatus used was a Brookfield Viscometer (Model – LVDV – II + P, DV II + Pro Viscometer) from IGene Labserve, New Delhi (Model LMDV-100).

Methods

Preparation of orange peel powder

Fresh oranges were washed and peeled. The peel was cut into strips (4.00 × 1.0 × 0.3 cm: length × width × height). The peel strips were blanched in drinking water (77 °C for 2–5 min; peel: water in a ratio of 1:2 w/v) to stop the undesirable changes caused by inherent peel enzymes.32. The blanched peel strips were placed in sodium bicarbonate (NaHCO3) solution (2.0%) for 3–4 min at 95 °C to reduce the bitterness and make the peels palatable12. The treated peel strips were subjected to osmotic dehydration by immersing them in sugar syrup (50 °Brix, 50 °C) for 4 hours and then freed from the adhering syrup. The osmotically dehydrated peels were dried in a vacuum dryer (45 ± 2 °C for 8 hours; 670 mm Hg column vacuum). The dried orange peel pieces (average moisture 7.21%) were ground in a food processor and sieved through a 35 U.S. stainless steel sieve to obtain powder with a particle size ≤ 500 µm. The photo of OPP is shown in Fig. 1.

Preparation of the yoghurt base

The weighed amounts of milk, skim milk and SMP required for a batch of 1.0 kg mix base (2.5% fat, 12.5% MSNF) were mixed, heated to 63 °C prior to homogenization (13.79 MPa and 3.45 MPa in the first and second stages respectively) and then heated to 90 °C/15 min and then cooled to 40 °C. Starter culture (Streptococcus thermophilus And Lactobacillus delbrueckii Subsp. Bulgarian1:1 v/v, hereinafter referred to as ST and LB) was added in an amount of 7.0 g/100 L milk and the milk was incubated at 40 ± 2 °C until 0.57–0.60 % LA of the yoghurt mass was reached. After this acidity was reached, the mass was cooled to 4 ± 2 °C.

Preparation of ice cream mixture

The amounts of milk, cream, SMP, sucrose and stabilizer-emulsifier required to produce a 3.0 kg portion of ice cream mix were calculated using the serum point method. Mixing the ingredients resulted in a base ice cream mix containing 7.43% fat, 12.50% MSNF, 21.50% sucrose, 0.27% stabilizer mix (pectin:carrageenan, 8:1 w/w) and 0.20% emulsifier (GMS). The mix was preheated to 68 °C, homogenized (13.79 MPa and 3.4 MPa) and then pasteurized at 80 °C/5.0 min. The pasteurized mixes were cooled to 4 ± 2 °C and matured overnight (12 h).

Preparation of frozen yoghurt

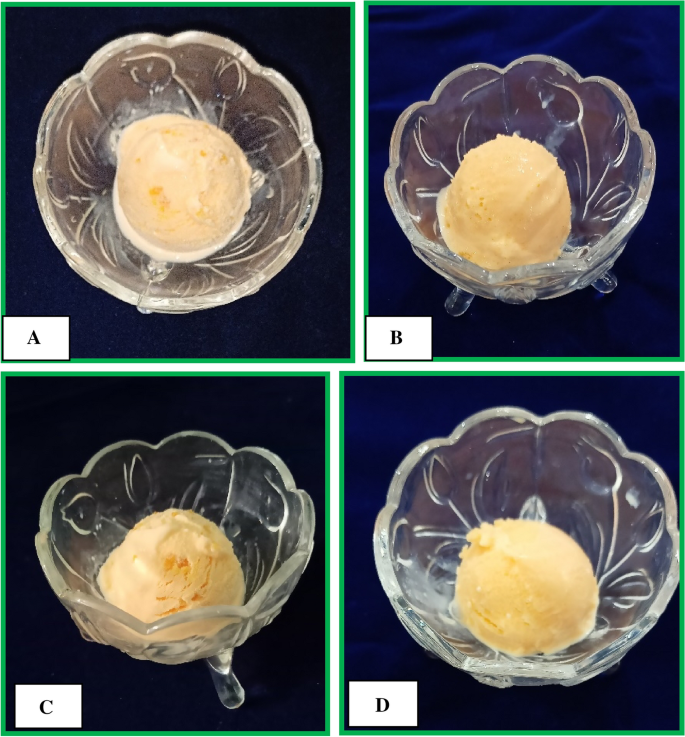

The ripened ice cream mix was mixed with a chilled (4 °C) unsweetened yogurt base in a ratio of 75:25 (w/w). Three batches of frozen yogurt (6.0% fat) were prepared as follows: (a) TC—Control with 9.0 % orange marmalade and 16.0 % sugar, (b) T1—1.5% OPP, (c) T2—2.5% OPP and (d) T3—3.5% OPP; to the last three samples (namely b, c, d) 9.0% orange juice and 16.0% sugar (by weight of the mixture) were added. OPP was added to the mixture immediately before pasteurization. The orange colorant prepared in previously boiled and cooled drinking water was added to the mixture before freezing (1.4 ml/kg of mixture). The orange juice was incorporated into the partially frozen mixture in a chilled (4 ± 2 °C) state. The ice cream-yoghurt base mixture was frozen in an ice cream freezer, filled into individual packets and then hardened for 2 hours in a jet tunnel hardener operated at − 23 °C. The hardened frozen yoghurt was stored in a deep freezer (M/s Blue Star, Thane, India) at − 18 ± 2 °C. The photographs of the frozen yogurt samples are shown in Figure 2.

Photos of frozen yogurt (A) Control and experimental products with OPP (B) @ 1.5 %, (C) @ 2.5% and (D) @ 3.5%

analysis

Orange peel powder

The OPP was analyzed for moisture, ash and total carbohydrates23. The crude fibre content (European Community No. 152, 2009) and β-carotene content (by HPLC-UV method) of OPP were analysed by the laboratory of Centre of Analysis and Learning in Livestock and Food (CALF), Anand, Gujarat, India. HPLC analysis was performed using the method described by Chiosa et al.31. Analyses were performed on an HPLC (Agilent), model LC 1100 series, equipped with a degasser, an automatic sampling injector, a high pressure pump and a multi-wavelength UV/visible detector. The mobile phase was acetonitrile-tetrahydrofuran-methanol-ammonium acetate (68.4% (v:v): tetrahydrofuran (THF) 22.0% (v:v): 6.8% (v:v): 2.8% (v:v) (1% (w:v)). The detection wavelength was set to 450 nm at a flow rate of 1.5 ml/min.

yogurt

The yoghurt was analyzed for moisture, fat, titratable acidity (TA) and ash using the standard method24.

Frozen yogurt

The frozen yogurt samples were analyzed for total solids (TS), protein and ash.25The fat content was determined using the method proposed by BIS.24. Total carbohydrate content was determined by difference. Analysis of crude fiber and β-carotene content of frozen yogurt was performed at the CALF laboratory in Anand, India.

Physico-chemical properties of frozen yogurt

The viscosity of the aged blend with the appropriate dosage of flavorings (e.g. orange crush) was analyzed at 20 °C using a Brookfield viscometer with RV spindle set (No. 63) at 100 rpm.26. The TA of the mixture base was determined using the standard method24. The melting resistance and overflow of frozen yoghurt were determined according to the method of Muse and Hartel.26 and Marshall et al.16 respectively.

Sensory evaluation of frozen yoghurt

A panel of 12 judges consisting of faculty members from SMC College of Dairy Science, Anand, India, performed sensory evaluation of frozen yogurt according to relevant guidelines and regulations. All experimental sensory protocols were followed as per the recommendations of the American Dairy Science Association and informed consent was obtained from all judges. Judges were initially selected using “duo-trio” and “triangle” tests. Frozen yogurt was served in high impact polystyrene (HIPS) cups (150 ml capacity) and at a temperature of − 13 ± 1 °C. Four-digit random codes were assigned to each sample and scored according to the American Dairy Science Association scoring card for the corresponding sensory attributes.16. This points card was for ice cream.

Statistical analysis

Data from duplicate frozen yogurt samples obtained in four replicates were subjected to statistical analysis using a completely randomized design; tests were performed at a significance level of 5.0%.27.

Ethical approval

A 12-member panel consisting of faculty members from the college conducted a sensory evaluation of frozen yogurt according to relevant guidelines and regulations. All experimental sensory protocols were followed according to the recommendations of the American Dairy Science Association and informed consent was obtained from all subjects.